3d scanning projector for Industrial Applications

The DLP3010 light control chipset from Texas Instruments targets industrial applications including 3D measurement, automated optical inspection, and medical imaging. The accompanying reference design published by TI and implemented in the TI EVM works well for evaluating the technology. However, this evaluation design has limitations for practical use.

Keynote Photonics’ LC3010 3D scanning projector addresses these limitations while preserving the DLP3010 chipset’s key functionality and improving performance. We designed the LC3010 from the ground up to be easily and quickly integrated into customers’ end equipment. Building on our experience with other products, we made careful design choices which improve all aspects of the product design: electrical, software, optical, mechanical, and thermal.

Examples of Keynote’s extensive improvements include:

Optocoupled Camera Triggering

Most structured light applications require synchronization of the projector’s pattern sequence with one or more connected cameras through the use of trigger signals. The TI reference design limits the trigger I/O voltage to 3.3V, and the trigger outputs (which are open-drain through large resistors) can only drive up to a few hundred microvolts before the signal voltage drops to unusable levels. Many of the most commonly used industrial cameras have optocoupled inputs which require much higher current on the trigger signals.

Keynote’s LC3010 offers optional high-current buffers which are capable of triggering any optocoupled camera as well as CMOS-triggered cameras. The trigger buffers supply any voltage from 3-20V (user supplied), or they can be jumpered on the LC3010 main connector to either 5V or 12V which are appropriate for optocoupled cameras.

In addition, the LC3010 5V tolerant trigger input improves compatibility with cameras or other triggering devices in applications where the projector timing is slaved.

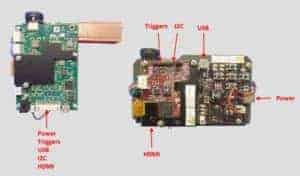

User connections

The TI reference design uses multiple connectors spaced widely apart around the projector. In a customer’s end equipment this has the potential to create routing difficulties for all the cables required.

On the Keynote LC3010 3D scanning projector all required connections are located at the rear of the projector. Separate connectors are provided for supply power and USB, but these are also provided on the main I/O connector. It’s possible for users to design a wiring harness to hook up everything on the LC3010 with only one connection.

(Note: HDMI video input requires an optional daughtercard for the LC3010)

The LC3010’s main I/O connector is also available as a vertical type to allow the main wiring to exit straight up from the driver board. Contact Keynote customer support for more information on this option.

All user connectors on the LC3010 are through-hole or use through-hole lugs to improve durability in industrial environments. In addition, the main I/O connector has retention features to help keep connections secure during vibration or thermal cycling.

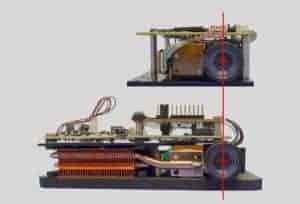

Mechanical

Ideal camera placement for many structured light applications is close to the projection lens on either side. This requires a relatively narrow form factor for the projector. The TI reference design uses a main board which is oriented perpendicular to the projector’s optical axis. This orientation complicates camera placement for 3D measurement systems.

Keynote’s LC3010 is narrower (when the heat pipe is replaced with a user-supplied heat sink for mass production), allowing more flexibility for camera placement.

In addition, our baseplate includes multiple mounting holes to provide attachment points for integrating the projector into customers’ end equipment.

DLP3010 Optical ENGINE

The TI reference design limits the maximum current levels of the illumination LEDs to 2.1A which is safe for continuous operation. However, structured light systems often use low operational duty cycles allowing them to operate at higher brightness levels without overheating. The Keynote LC3010 3D scanning projector provides up to 6A for the extra brightness sometimes needed for 3D measurements in adverse factory conditions.

The optical engine used in both the TI reference design and Keynote’s LC3010 has a rotating projection lens barrel to allow focus adjustment over a range of distances. Since industrial environments may have vibration or thermal cycling, this adjustment may slip, so Keynote added a screw to lock it in place.

Thermal management

Projectors are often operated at high brightness in demanding industrial environments. As a result, thermal management becomes a key aspect of structured light system design. End equipment designers often choose to manage the heat generated by the projector as part of a larger system-level approach. The LC3010 is available with a standard heat pipe attached to its illumination LEDs. Detailed mechanical information is available to enable customers to integrate the projector with a heat dissipation design tailored for their application. The LC3010 provides access to a thermistor embedded in the optical engine and the temperature can be monitored with software. If preferred, the embedded thermistor can be unplugged and a user-supplied 100K NTC thermistor can be connected instead. This provides the option of monitoring the temperature elsewhere in the system.

DLPC3478: Integrated, Multi-Platform API and GUI

The LC3010 API and overall development software environment is designed to support customer software development and mass production. We can support libraries in both Windows and Linux environments.

Keynote’s LC3010 graphical user interface (GUI) is designed for rapid software development in collaborative engineering environments. Structured light applications often require managing large libraries of stored patterns and multiple variations of pattern sequences. Keynote’s software simplifies this process by allowing the user to save pattern set and sequence descriptors as .csv files which can be built or modified with text editing tools. These files can be easily shared between designers and uploaded into the GUI’s tables to rapidly update an LC3010 projector while developing applications.

Each Keynote LC3010 can be programed with up to 65536 unique solutions. These solutions store complete projector configurations including pattern sequence parameters, LED levels, peripheral settings, etc. Setting a solution as the default allows the LC3010 to power up in a fully ready state without user intervention.

A Complete Package

Keynote Photonics’ LC3010 3D scanning projector provides a comprehensive solution to 3D measurement applications with a robust product design and development environment. We look forward to serving your needs and understanding any specific requirements you have. You can download the product user guide here and follow-up with any questions here.